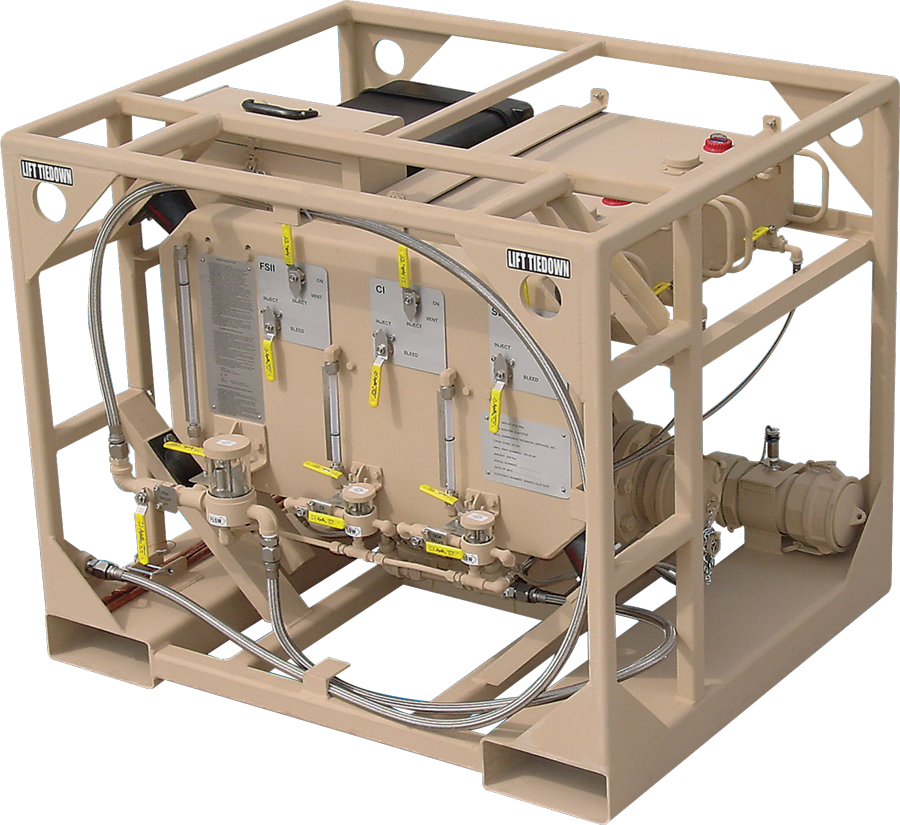

The TPI-4T-4A-1 utilizes Hammonds proven additive injection systems to produce military specification JP-8 jet fuel by injecting FSII, CI and SDA additives. Each additive is delivered continuously and is blended evenly at ratios from 4-2500 ppm.

- Accurate additive dosage

- Thorough, complete blending

- Easily transportable

- Sturdy, solid construction

- Available in a cart configuration

SPECIFICATIONS

- Number of additives: 3 standard, 4 optional

- Injection Ratios: Three additives: (1) 0-1,500 PPM (2) 0-65 PPM Four additives: (1) 0-1,500 PPM (1) 0-275 PPM (2) 0-65 PPM

- Minimum injection ratio: 10 PPM standard

- Normal operating range: 100-1,000 GPM (378-3785 liters per minute)

- Minimum product flow rates: 50 GPM (189.21) (minimums vary with line pressure)

- Product temperature: 40°F to +250°F (-40°C - 121.1°C)

- Maximum product line pressure: 125 PSI (8.8 kg/cm) (PSI max varies with injection ratios, higher pressure pumps are available as options)

- Maximum hydrostatic pressure: 350 PSI (24.6 kg/cm)

- Product viscosities: to 10,000 SSU

- Products handled: oils, fuels, chemicals

- Duty cycle: continuous

- Fluid connections - product: 6” (15.24 cm) cam lock, additives: ¼” (.6 cm) NPT or ¾” (1.9 cm) NPT

CONSTRUCTION MATERIALS

- Fluid Motor: All hard anodized aluminum with stainless steel shaft

- Injectors: All wetted parts 300 series stainless steel with Teflon® trim

- Mechanical Seal: Carbon on ceramic

- Model 800 driver